See an update on Meati here.

Critical need for this technology

With a growing global population, there is an ever-increasing demand for carbon-based materials used in applications such as energy storage, filtration, and catalysis. Conventional production of porous carbon materials consumes non-renewable or limited feedstock materials, such as coal, wood, or coconut husks. The development of efficient manufacturing methods, using sustainable feedstocks, and with the smallest energy use and greenhouse gas footprint possible, is needed to meet growing demand without causing environmental and societal harm.

Recently carbon-based nanomaterials have shown unprecedented physical and chemical properties such as high strength, excellent resistance to corrosion and exceptional electrical and thermal conduction and stability. Because of these unique features, carbon-based materials are in high demand for products across many fields, but new manufacturing methods are costly and energy intensive and can have negative environmental impacts. However, those based on energy efficiency and renewable feedstocks have competing applications with lower cost and external impacts.

Supplemental needs for this technology

- The Emergy platform can produce low cost, high performance, carbon-based materials with different characteristics targeted for specific applications such as energy storage, filtration, and catalysis.

- It can replace refined petroleum, mined graphite, and geographically and supply limited biomass as a feedstock materials, which would help reduce the US dependence on foreign imports or unsustainable biomass harvesting/production.

- The elimination of energy intensive processing steps used to in the traditional production of carbon will further reduce greenhouse gas emissions.

Potential CO2 Reduction

Animal-based meat production is responsible for approximately 5,000 MtCO2e of emissions annually and this amount is projected to increase as standards of living and incomes rise around the world. Fungi-based protein substitutes reduce emissions by 67-93% relative to an equivalent amount of animal-based meat, so wide adoption of their technology has the potential reduce thousands of MtCO2e of emissions each year.

Competition

- Waste2Watergy, an Oregon State University-based startup producing electricity during wastewater treatment.

- Emergy advantage: Much lower capital and operation costs.

- Breweries developing biogas production strategies.

- Emergy advantage: Much lower capital and operation costs. Allows breweries to focus on brewing beer.

- Commercial manufactures of porous carbon from feedstock, including coal, wood, nutshells and coconut husks

- Emergy advantage: Does not require expensive and energy intensive processing steps. Tunability in the growth stage unlocks in a single process transition properties such as variations in chemistry, dopants and microstructure. Surface area and purity levels for Emergy’s product are greater than conventional materials.

- Emergy cost estimate: $51 per ton using industrial waste streams and $381 per ton without versus $800 to $2,500 per ton for traditional products, depending on quality.

- Emergy advantage: Does not require expensive and energy intensive processing steps. Tunability in the growth stage unlocks in a single process transition properties such as variations in chemistry, dopants and microstructure. Surface area and purity levels for Emergy’s product are greater than conventional materials.

- Commercial manufactures of mined graphite or refined petroleum used for electrochemical applications.

- Emergy advantage: Does not generate harmful emissions or toxic mining byproducts. Does not require expensive and energy intensive processing steps. Tunability in the growth stage unlocks in a single process transition properties such as variations in chemistry, dopants and microstructure.

- Emergy cost estimate: $51 per ton using industrial waste streams and $381 per ton without versus $8,000 per ton for traditional products.

- Emergy advantage: Does not generate harmful emissions or toxic mining byproducts. Does not require expensive and energy intensive processing steps. Tunability in the growth stage unlocks in a single process transition properties such as variations in chemistry, dopants and microstructure.

Potential markets

- The initial target market is device manufactures filtering/refining water, oil and natural gas, chemicals, and biofuels.

- Follow-up markets include supercapacitor and fuel cell electrode manufacturers and carbon black supplies.

Value proposition: Compared to traditional porous carbon production processes, Emergy’s platform technology produces a lower cost and in many cases, higher performing material, that can be produced near the customer to reduce distribution costs, logistics, and have lower negative environmental impact.

Key innovation

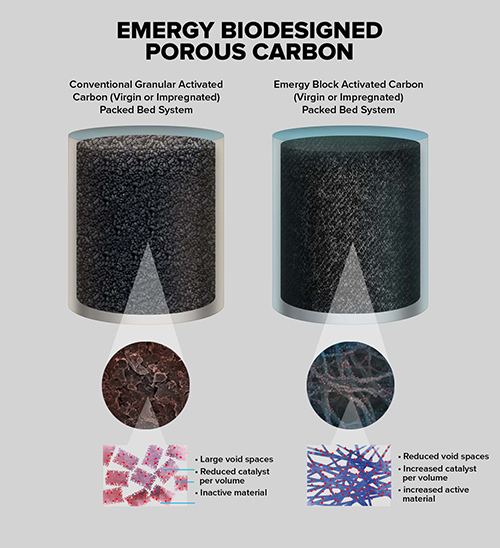

Emergy’s platform technology uses a filamentous organism to capture renewable and sustainable carbon from wastewater as a base for creating a variety of tunable porous carbons. These materials are cheaper to manufacture and have a smaller environmental impact than current carbon-based products.

R&D status of product

Emergy has currently produced several pre-commercial prototype materials, such as a lithium-ion anode, supercapacitor electrode, and solid block filter. Emergy is also working with Avery brewing company to test wastewater treatment efficiency and materials production.

Team Overview

Co-Founder

Tyler Huggins

A Ph.D. in environmental engineering from the University of Colorado, Boulder. A master’s degree in environmental and sustainability engineering from the University of Colorado, Denver. A bachelor’s degree in biology from the University of Montana.

Co-Founder

Justin Whiteley

A Ph.D. and master’s degree in mechanical engineering from the University of Colorado, Boulder. A bachelor’s degree in mechanical and nuclear engineering from the University of California, Berkeley.

Advisors

Dr. Jason Ren

A professor at the University of Colorado Boulder that specializes in resource recovery during wastewater treatment. Dr. Ren is well respected in both the private and public sectors, has raised millions of dollars in funding, and has several patented and licensed inventions.

Dr. Sehee Lee

A professor at the University of Colorado Boulder that specializes in developing new and advanced energy storage materials and devices. Several battery-based start-up companies have been launched out of his lab, including Solid Power and Silion.

Background Resources

Video: Beer to Batteries – A CU Boulder Innovation

Video: How Emergy’s Biodesigned porous carbon can increase your company’s margin

Fact sheet: Biodesigned porous carbon enables customized performance

Infographic: Emergy technology comparision

Relevant Publications

Controlled Growth of Nanostructured Biotemplates with Cobalt and Nitrogen Codoping as a Binderless Lithium-Ion Battery Anode ACS Appl. Mater. Interfaces, 2016, 8 (40), pp 26868–26877

DOI: 10.1021/acsami.6b09300

Company Profile

- Total Amount Raised: 0

- Status: Private

- Year Founded: 2015

- Patents: 2 provisional

- Primary Industry: Industrial filtration, energy storage

- Category: Carbon materials, manufacturing processes

- Estimated annual revenue: $10M

- Employs: 2 people

- Social Challenge: Sustainable energy and energy-efficient manufacturing

- R&D commercial collaborator: None