While at the Material Engineering Research Facility (MERF), part of the Department of Energy’s (DOE) Argonne National Laboratory, Volexion has also successfully scaled up its coating capacity by a hundredfold and demonstrated the applicability of its coating with a diverse list of emerging, industry-grade cathode materials, said “Ted” Jung Woo Seo, Volexion’s cofounder and director of research and development.

Making LIBs last longer for electric vehicles, drones and other consumer products could be more attractive to consumers eager for a quality product. Ensuring those batteries last longer and still have lower manufacturing production costs could ultimately help boost the entire industry.

“Volexion technology has the potential to enable emerging LIB active materials with high theoretical energy densities that are too unstable for commercialization yet. For electric vehicles, for example, this means lighter batteries with longer driving range, without concerns over reduced performance during long winter days in Chicago,” said Seo.

Developing the technology

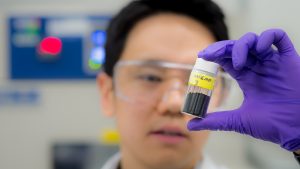

Seo is currently part of the DOE’s Chain Reaction Innovations (CRI) program, the entrepreneurship program at Argonne that embeds innovators into the lab for a two-year period to develop their technology. His company has developed a patented coating additive based on graphene nanomaterial that improves the overall performance of LIBs. His team utilizes patented and scalable graphene production methods to apply conformal coatings on cathode

particles, which stabilize against interfacial degradation and side reactions to help maximize the cycle life and power performance of LIBs while also minimizing their size.

What differentiates Volexion technology is its innovative yet simple methodologies, which do not require energy-intensive processes, such as high temperature or chemical reactions. This leads to high scalability and flexibility in terms of target cathode applications, underlying its compatibility with existing battery manufacturing infrastructure and resulting in a lower barrier for industry adoption. Volexion’s performance improvement under cold temperatures also may address the unique environmental operability challenges faced by emerging applications, including electric vehicles and drones, according to Seo.

Volexion, founded in 2018, was spun out of Professor Mark Hersam’s lab at Northwestern University, with Seo and Hersam now leading the technical and business development efforts of the company. Seo, who earned his Ph.D. in materials science and engineering from Northwestern, took the technology to CRI. Seo is part of CRI’s second cohort, which started at Argonne in June 2018.

Matchmaking

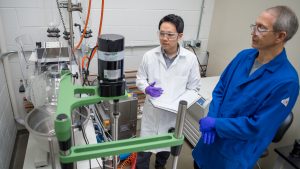

Seo, who has 20 co-authored publications, three issued patents and two more patents pending in the field of nanomaterials and their applications, said CRI plays the role of a “matchmaker” between each company/technology and scientist/facility at Argonne. Volexion found a perfect fit at Argonne’s MERF.

“Our technology is on a critical pathway towards commercialization, where it needs to successfully scale-up and demonstrate technical validation at the level of industry,” said Seo.

“We develop scalable processes for making advanced battery materials and Ted’s technology can potentially further improve performance of the materials.”

Krzysztof Pupek, Material Engineering Research Facility Team Lead

Seo has been using resources that are unique to Argonne and that he likely could not do without. He especially notes Argonne’s capacity to synthesize industry-quality cathode materials with unique, tailored properties in large scale. He also uses the diverse battery material processing equipment that are essential for his firm’s scale-up efforts. He taps MERF’s expertise in other areas of LIB materials, such as advanced electrolytes, which may lead to potential future collaborations made all the more convenient by the close proximity that eliminates concerns over transportation of sensitive samples and enables more in-person discussions, he said.

Volexion’s mission is aligned with MERF expertise, resources and leading scientific resources.

“Ted is a very talented researcher and also has been a quick study in his development as a businessman,” said Joseph A. Libera, Seo’s principal investigator at Argonne. “The technology Ted is developing has significant potential to enhance the battery performance of Argonne’s

battery materials and there is a strong possibility of future collaboration with Argonne in addition to the commercials avenues he is exploring.”

Krzysztof Z. Pupek, Seo’s team leader at MERF, said Seo is a team player who is easy to work with.

“I see a value in technology he is developing and, as a group leader, I try to help him as much as possible by making the MERF resources available to him,” said Pupek. “His work is complementary: we develop scalable processes for making advanced battery materials and Ted’s technology can potentially further improve performance of the materials. Working together, we successfully demonstrate synergistic relationship between Argonne and a just-born startup company.”

In terms of business development, CRI has been providing workshops and networking opportunities to help grow the technology through customer discovery efforts and understanding of their pain-points, which will continue to shape their overarching technical objectives and business model, Seo said.

“CRI has been pushing me to challenge myself beginning from the application phase, and especially driving me to shape my thinking as an entrepreneur,” said Seo. “CRI is also helping me build the essential skill set as we strive to bring our technology from inside the laboratory to real markets and customers. On a personal level, I think CRI opened up opportunities for me to

learn how to express and evaluate technical ideas with a business-focused mindset.”

Seo notes Argonne is one of the leaders in the field of advanced LIB technologies, both in the eyes of academia and industry, making it the perfect home his emerging LIB technologies to accelerate technical progress and validate commercial potential.

Read more about the impact of CRI innovators.