A million times thinner than paper, more conductive than copper, and stronger than a diamond, graphene has boundless potential, including playing a role in solving the world’s water and energy crises.

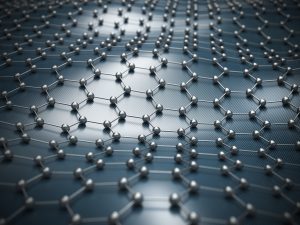

Dubbed a “wonder” material, graphene is a two-dimensional mesh of carbon atoms arranged in the shape of a honeycomb lattice. Despite its promise, current graphene production methods are limited by high manufacturing costs, as well as health and environmental risks. Perhaps more importantly, graphene itself is not soluble in any solvent, making it difficult or impossible to use in promising applications because it cannot be integrated into composites or polymer solutions.

Hoping to revolutionize the graphene market, Arsheen Allam, founder and CEO of GOLeafe, developed a production method that overcomes these challenges.

Allam’s patented technique uses organic materials and energy-efficient processes to extract water-soluble graphene oxide from carbon waste materials in an ecofriendly, cost-effective way.

Allam, a Chain Reaction Innovations (CRI) Cohort 5 innovator, founded GOLeafe in 2021 to develop low-cost graphene-oxide-based clean energy technologies.

“Our process extracts graphene oxide from diverse sources of carbon waste streams, which minimizes dependency on a single source of raw material,” Allam said. “For example, we adapted our process to extract graphene from waste tires. Forty-five percent of the 250 million tires generated annually end up in landfills.” – Arsheen Allam

GOLeafe scientists and engineers are developing a graphene-based water filtration membrane, a next-generation solution to provide fresh, potable water. The team has also developed a graphene-based super capacitor, a potentially green alternative to lithium-ion energy storage devices.

“Our goal is to build a fully integrated system for renewable energy capture and storage, and for filtration, all based on the same green, nontoxic graphene technology,” Allam said.

Allam, a materials scientist and engineer with an MBA from Duke University and a Forbes 30 Under 30 awardee, joined CRI at the U.S. Department of Energy’s Argonne National Laboratory in June 2021. CRI is a two-year entrepreneurship program that embeds innovators in the Lab to help them develop and de-risk their early-stage technologies.

During the CRI program, Allam is working with Yuepeng Zhang, a principal scientist in Argonne’s Applied Materials Division, as well as other technical staff throughout the Laboratory.

HOW IT WORKS

Typically, graphene is produced through mechanical or chemical exfoliation, energy-intensive processes that use harsh chemicals and yield relatively little usable graphene.

Allam’s process extracts graphene oxide from natural substances like grass, wood, hay, and lignite, eliminating the need for harsh chemicals as well as reducing capital costs and energy-intensive equipment.

“GOLeafe uses carbon waste streams as the starting material, which is not just a cost advantage,” Allam said. “We are also creating a circular economy for end-of-life carbon. This has a significant impact on reducing carbon emissions.”

GOLeafe’s method has two times less GHG emissions than chemical exfoliation and six times less GHG emissions than the mechanical exfoliation method.

Graphene can also be used to enhance products in industries such as paints and coatings, construction, and packaging materials.

Access to equipment in Argonne’s AMD and Materials Engineering Research Facility is helping Allam optimize the graphene oxide production process and ensure product consistency and quality through characterization and testing.

“Argonne provides access to equipment GOLeafe did not otherwise have. For example, I will be using electrospinning technology with Dr. Zhang to create graphene-embedded membranes for water filtration,” Allam said.

THE IMPACT

Driven by a lifelong passion to bring clean water to underserved populations, Allam launched her first business, CNanoz, Inc., in 2012 to design and build water purification systems. Realizing that nanocarbon filtration works well for ground and river water, but not saltwater, Allam turned to graphene as a potential desalination solution when she founded GOLeafe.

“Because 97% of the world’s water is saltwater, we need desalination to bring fresh water to those lacking access throughout the world, including the U.S.,” she said.

After developing the innovative, low-cost graphene oxide production process, Allam worked with a team of engineers to develop the capacitive deionization (CDI) system. CDI is a membrane-free graphene-based filtration technology that uses as much as 75% less energy than reverse osmosis, the most common method of water desalination.

At Argonne, Allam is testing graphene and graphene derivatives on various substrate materials. Her goal is to create a desalination membrane to incorporate into the CDI system to enhance its filtration capabilities.

Allam ultimately hopes to build a self-sustaining, portable desalination unit to bring clean water to underserved areas across the globe. The idea is to use graphene as both the energy source and the filtration technology.

MOVING FORWARD

Allam is prototyping the desalination membrane and super capacitor. GOLeafe was granted a patent for its proprietary graphene oxide production process from carbon waste and has filed to patent the graphene-based super capacitor.

Along with access to world-class technology and talent, Allam credits CRI for providing funding that allowed her to pursue GOLeafe full time. Overall, CRI provides innovators with over $400,000 in direct non-dilutive support during the two-year program.

“Without the financial stability from Chain Reaction Innovations, it would have been difficult to accomplish the goals I set for GOLeafe,” Allam said. “This unique program is really a game-changer.”