The innovation is the creation of New Jersey-based RenewCO2, which was co-founded in 2018 by Chain Reaction Innovations’ (CRI) fellow Karin Calvinho while she was a Rutgers University chemistry Ph.D. candidate; Anders Laursen, a postdoc at the time; and Professor Charles Dismukes.

“Our mission is to enable companies to meet carbon neutrality goals by using their CO2 emissions to make revenue-generating, renewable products,” Calvinho said.

Calvinho joined CRI’s Cohort 4 at the U.S. Department of Energy’s (DOE) Argonne National Laboratory in August 2020. CRI is a two-year entrepreneurship program that embeds innovators in the Lab to help them develop their early-stage technologies. While embedded, Calvinho is working with Dr. Theodore Krause, an Argonne chemical engineer and Fuel Cell group leader.

ABOUT RENEWCO2

While CO2 conversion has been around since the 1980s, no other commercial CO2 electrolyzer produces RenewCO2’s specialty—monoethylene glycol (MEG)—which is used to make polyester clothing and polyethylene terephthalate (PET) plastic bottles.

Since joining CRI, RenewCO2 has improved the performance and stability of the catalysts used in the electrolyzer. In February, the startup received a $25,000 matching Small Business Innovation Research (SBIR) grant from the State of New Jersey. Then in May, RenewCO2 received $1.1 million in SBIR Phase II funding from DOE.

“The societal benefit is really the climate impact and the ability to use electricity in the chemical industry to make greener chemicals,” –Karin Calvinho

DOE is interested in potentially using the electrolyzer to capture CO2 from coal plants for conversion to MEG, which would help decarbonize the power generated while preventing an increase in consumers’ electric bills.

IMPACT

By recycling CO2 emissions into useful products, RenewCO2’s technology can help mitigate climate change, Calvinho said.

If all MEG manufacturers adopted RenewCO2’s carbon negative production technology, global CO2 emissions could potentially be reduced by 91.6 Mton (million metric tons; 0.27% of global emissions) per year, the equivalent of the annual carbon emissions of 5.7 million average Americans.

“The societal benefit is really the climate impact and the ability to use electricity in the chemical industry to make greener chemicals,” Calvinho noted.

With changes in the catalyst, the electrolyzer platform can also make other products, such as formic acid (used in leather tanning and agriculture) and may even be used to produce fuel in the future, resulting in even greater climate impact.

HOW IT WORKS

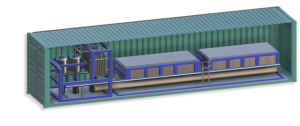

RenewCO2’s product, in its final form, is about the size of the 40-foot metal shipping container. Each module contains an electrolyzer whose electrodes are coated with a proprietary catalyst. CO2 and water are the only process inputs, producing MEG in a single step and oxygen as a by-product. After conversion, excess water is evaporated to produce high-purity MEG, Calvinho said.

An electrolyzer is “a chemical reactor in which the reaction is driven by electricity.” It usually runs 24/7 and removes 1.42 tons of CO2 for every ton of product made.

A company that produces MEG with a traditional petrochemical process, for example, can pipe their CO2 stream (ethylene oxidation by-product) into the electrolyzer, yielding a MEG capacity expansion with comparable cost to the petrochemical process.

Follow this link to see a diagram that explains electorchemical technology in more detail.

PROTYPING

The RenewCO2 fully functional laboratory prototype is the size of a wallet, producing milligrams of product per day. The company is aiming to build an electrolyzer pilot by 2023 that is roughly the size of a suitcase, with capacity to make 1 ton of product/year. In 2025, RenewCO2 plans to reveal a commercial shipping container-sized product capable of handling 3 tons of CO2 per day.

Karin Calvinho is a member of cohort 4, the fourth class of fellows to participate in the Chain Reaction Innovations program at Argonne National Laboratory.

Chain Reaction Innovations provides innovators with laboratory tools and seed capital as well as the technical, business and manufacturing expertise needed to rapidly mature their early-stage technologies. The goal is to enable them to attract the long-term capital and commercial partners needed to scale and launch their startups into the marketplace.

CRI is part of the Lab-Embedded Entrepreneurship Programs supported by the U.S. Department of Energy’s Office of Energy Efficiency and Renewable Energy (EERE). EERE created the Lab-Embedded Entrepreneurship Programs to provide an institutional home for innovative postdoctoral researchers to build their research into products and train to be entrepreneurs. The two-year program for each innovator is funded by EERE’s Advanced Manufacturing Office (AMO).