SOLUTIONS FOR DISPLAYS

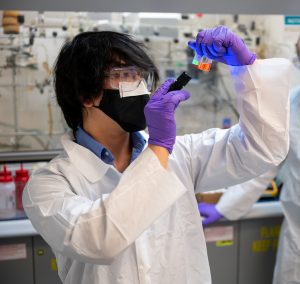

Yu Kambe, Ph.D., co-founder and CEO of NanoPattern Technologies, as well as a Cohort 3 innovator in the Chain Reaction Innovations program, is seeking to provide a solution for these up-close displays with his company’s quantum dot ink, which is made of nanoparticles.

“We can pack nanoparticles at really high density compared to all our competitors,” Kambe said.

The tighter density of nanoparticles provides a better quality image, avoiding a display screen that looks pixelated up close.

Kambe joined CRI’s Cohort 3 at the U.S. Department of Energy’s Argonne National Laboratory in June 2019. CRI is a two-year entrepreneurship program at Argonne, which embeds innovators in the Lab to help them grow their early-stage technologies.

While embedded, Kambe has worked at Argonne’s Center for Nanoscale Materials (CNM) with Argonne’s physics lead Richard Schaller, who has expertise in ultra-fast spectroscopy and quantum dots.

“We can pack nanoparticles at really high density compared to all our competitors,” Kambe said.

As part of Cohort 3, Kambe has reached several important milestones for his company – achieving sustainable funding and technological de-risking, demonstrating that his product is technologically capable of doing what his company claims.

NanoPattern Technologies received not only funding from CRI, but also from a Small Business Innovation Research (SBIR) grant from the National Science foundation in the amount of $225,000, as well as $25,000 in funding from a Fortune 500 Company. NanoPattern de-risked its technologically by demonstrating pixel resolution and optical density.

HOW IT WORKS

NanoPattern’s quantum dot ink is made out of semiconducting nanoparticles in a dispersion, specifically indium phosphide.

A small portion of the ink is manufactured by NanoPattern, usually sent to the companies who purchase it in a glass vial, amber plastic bottle, or bladder pack. Most of NanoPattern’s sales, however, are for “instructions to make the ink,” Kambe said.

The company purchases the ink or instructions, then turns the quantum dot ink into a film on a display screen.

“Our ink is kind of like a liquid version of a color filter,” Kambe said.

Color filters are currently used on most flat screen TVs to create a color image.

With the quantum dot ink, however, the high density particles provide a higher-quality, less pixelated image than color filters do and convert color with 99 percent efficiency. Quantum dot ink is quantum because of a “really interesting property,” he said.

THE TECHNOLOGY

When blue light is absorbed through the quantum dot nanoparticles, the light is re-emitted as green or red light.

“By making it a nanoparticle, you confine the process of absorption, Kambe explained.

Think of an apartment building, Kambe said. If you went up the stairs to the second floor, but the ceiling was too low and the door too tiny for you to enter, you would have to try the third floor and keep on trying until you reached a floor that had a high enough ceiling and door for you to pass through.

Due to the small size and density of the nanoparticles, the light cannot pass through at the wavelength that it came in, but rather must pass through at a different wavelength. The different wavelength results in a different colored light. This step conversion is a quantum effect.

“It’s so small, it has this confining, quantum effect,” Kambe said.

This tininess is what makes quantum dot ink so effective. View a presentation on the complexity of NanoPattern’s technology here.

Yu Kambe is a member of cohort 3, the third class of innovators to participate in the Chain Reaction Innovations program at Argonne National Laboratory.

Chain Reaction Innovations provides innovators with laboratory tools and seed capital as well as the technical, business and manufacturing expertise needed to rapidly mature their early-stage technologies. The goal is to enable them to attract the long-term capital and commercial partners needed to scale and launch into the marketplace.

CRI is part of the Lab-Embedded Entrepreneurship Programs supported by the U.S. Department of Energy’s Office of Energy Efficiency and Renewable Energy (EERE). EERE created the Lab-Embedded Entrepreneurship Programs to provide an institutional home for innovative postdoctoral researchers to build their research into products and train to be entrepreneurs. The two-year program for each innovator is funded by EERE’s Advanced Manufacturing Office (AMO).