For decades, scientists and manufacturers wanted to make hydrogen fuel cells better and more efficient so this clean form of energy, which emits water vapor instead of CO2, would be adopted and help decarbonize the planet.

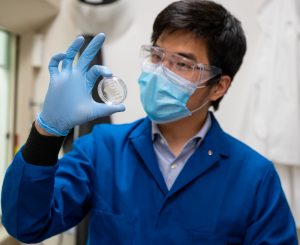

Gary Ong, the co-founder and CEO of Celadyne Technologies and a Chain Reaction Innovations’ (CRI) Cohort 3 innovator, invented a fuel cell nanocomposite membrane that helps make hydrogen fuel cells more affordable and efficient.

“If you want people to use (hydrogen) fuel cells…you just have to make the fuel cells better,” said Ong, who has a Ph.D. in Materials Science and Engineering from the University of California, Berkeley.

CLIMATE IMPACT

Hydrogen, as a vector for energy, is a critical component to enable deep decarbonation of industries ranging from heavy duty manufacturing and cargo transportation to fertilizer production and long duration grid storage.

The climate impact of these industries—manufacturing, electricity generation and storage, and trucking—accounts for over 50 percent of US greenhouse gas emissions. The Hydrogen Council, a consortium of stakeholders in hydrogen, estimates that a transition to a hydrogen-based energy infrastructure can generate $2.5 trillion in economic value and 30 million new jobs.

Hydrogen also has the potential to bolster US energy security. Ong observes, “Hydrogen infrastructure and availability is actually much better in the US than in many other places in the world so hydrogen is a more suitable solution here. That’s why Celadyne sees hydrogen fuel cells as a particularly good strategy to achieve deep decarbonization, given the availability of this framework.”

ABOUT CELADYNE

Ong joined CRI Cohort 3 at the U.S. Department of Energy’s Argonne National Laboratory in June 2019. CRI is a two-year entrepreneurship program at Argonne, which embeds innovators in the Lab to help them grow their early-stage technologies. While embedded, Ong has worked with John Kopasz, an Argonne chemist with expertise in fuel cells.

“If you want people to use (hydrogen) fuel cells…you just have to make the fuel cells better,” said Ong,

Since joining, Ong’s Celadyne Technologies has reached several milestones. These milestones include raising a total of $1.45 million in non-CRI funding, expanding from a team of two (Ong and co-founder Delia Milliron) to a team of what will soon be six people, improving the conductivity of the nanocomposite membrane, establishing a laboratory outside of Argonne (due to COVID-19), and three industry recognition awards.

HOW IT WORKS

Celadyne’s nanocomposite membrane is composed of ultra-small ceramic particles embedded in a polymer whose unique properties derive from the interface where these two dissimilar classes of materials meet. Each ceramic particle is very small, about 4 nanometers or about 25,000 times smaller than the width of a human hair, Ong said.

“The trick to getting these old materials to do new tricks is to focus on the interface,” he said. “When things are this small, most of the material consist of interfaces.”

In a fuel cell, there are multiple nanocomposite membranes that when stacked together (hence the name fuel cell stack) can be anywhere from the size of a human hand to the size of a laptop, depending on the fuel cell size and the application in mind. A basic, hydrogen fuel cell stack is composed of the membrane, surrounded by a catalyst, with a metal plate on the outside to conduct the electricity generated from the reaction.

The nanocomposite membrane, which can operate at higher temperatures, provides more efficiency so fewer stacks are needed, resulting in a smaller size and lower cost, Ong said.

Celadyne has not started manufacturing yet, but may explore processing this fall.

The company would ideally like to do contract manufacturing with a third party and sell hydrogen fuel cell stacks for unmanned aerial vehicles (UAVs), along with rolls of the nanocomposite membrane that can also be used for heavy-duty fuel cells, electrolyzers, and electrochemical compressors.

Celadyne’s nanocomposite membrane is less toxic, safer to manufacture, and will likely be recyclable, unlike other membranes on the market.

Ong said that he started Celadyne because he wanted to improve hydrogen technology, help decarbonize the world, and realize the business benefit of the nanocomposite membrane, which can be used for three components of the hydrogen system (fuel cell, electrolyzer, and electrochemical compressor). He also wants to create a legacy.

“When Celadyne succeeds — someday when someone points to a hydrogen fuel cell, it will be a Celadyne membrane at the heart of the fuel cell,” Ong said. “That makes it all worth it.”

Gary Ong is a member of cohort 3, the third class of innovators to participate in the Chain Reaction Innovations program at Argonne National Laboratory.

Chain Reaction Innovations provides innovators with laboratory tools and seed capital as well as the technical, business and manufacturing expertise needed to rapidly mature their early-stage technologies. The goal is to enable them to attract the long-term capital and commercial partners needed to scale and launch into the marketplace.

CRI is part of the Lab-Embedded Entrepreneurship Programs supported by the U.S. Department of Energy’s Office of Energy Efficiency and Renewable Energy (EERE). EERE created the Lab-Embedded Entrepreneurship Programs to provide an institutional home for innovative postdoctoral researchers to build their research into products and train to be entrepreneurs. The two-year program for each innovator is funded by EERE’s Advanced Manufacturing Office (AMO).