This is the first major round of funding for the start-up, formerly known as Emergy, which was part of Cohort 1 in the Department of Energy’s (DOE) Chain Reaction Innovations (CRI) program. Emergy said the capital infusion validates its technology and business model and enables it to plan for its growth.

“What got the investor’s ears perking up was the simultaneous benefit of producing healthy and delicious protein while reducing production costs compared to conventional methods,” said Tyler Huggins, Emergy’s chief executive officer. “At scale, Emergy believes it is possible to bring the cost of protein production down to less than half the cost of wholesale chicken.”

“Our technology has the potential to feed millions of people high-quality, cost-competitive protein that has ‘orders of magnitude’ less environmental burden than traditional methods,” said Justin Whiteley, Emergy’s chief technology officer.

The $4.8 million is in addition to $350,000 received from DOE and National Science Foundation (NSF) Small Business Innovation Research (SBIR) grants, which helped to fund research and add two employees. The new funding came as Huggins and co-founder Justin Whiteley wrapped up a two-year stint in CRI, the entrepreneurship program at Argonne National Laboratory, that provided the pair with the resources and facilities they needed to help them enhance their skills in the lab and develop their technology into a business. It especially supported Tyler and Justin’s growth by facilitating networking opportunities with industry executives to help establish the viability of their new technology. CRI helps to reduce the barriers to success for hard-tech scientists who want to commercialize high-risk, high-reward technologies.

Brewing Innovation

Though it started as a mere idea four years ago “over a couple of beers” according to Huggins, Emergy is now a venture-backed industrial biotechnology company. It focuses on redesigning the way protein is produced to make healthy and nutritious food that is affordable.

Huggins and Whiteley met during their Ph.D. studies at University of Colorado Boulder in 2015 and connected on the idea of using the efficiencies of biological systems and advanced in with material science to help improve manufacturing and the performance of various products. Combining Whiteley’s expertise in advanced battery materials with Huggins’ work in environmental engineering, their first project was using biological templates to produce battery electrodes that could outperform conventional flaked graphite in lithium ion batteries. To improve the resource requirements of this process, they also developed a way to use leftovers from the beer brewing process as the only raw material input, making it almost completely energy, water and emissions neutral.

“Who thought drinking beer could help with energy independence?” said Huggins.

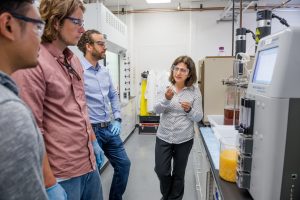

In 2016, Emergy was accepted into CRI to spend two years embedded at Argonne as they de-risked and developed their envisioned biomanufacturing process. As part of the CRI program, Emergy connected with Meltem Urgun-Demirtas, the leader of the Biosciences and Reactive Separations Group in the Applied Materials Division. Not only did Urgun-Demirtas help to provide access to laboratory equipment and a safe space to rapidly develop their core concept, she provided advice as they developed their ideas, pivoted to different product approaches, and tested their technology.

“CRI has given us the flexibility to make these pivots and rapidly iterate the manufacturing process and product.”

Justin Whiteley, Chief Technology Officer, Emergy Foods

Urgun-Demirtas praised Huggins and Whiteley as a high-energy team that worked hard to scale their process.

“They showed those of us at Argonne that their process could scale up and they were doing it all while testing, searching for funds and meeting the full demands of CRI,” Urgun-Demirtas said.

During this time, Emergy also was given the valuable opportunity to evaluate their business model to address the most pressing market needs, while providing the biggest societal and environmental benefits.

Emergy was able to demonstrate numerous applications for its technology, both in energy storage and water filtration, and worked with a multitude of companies in validating the performance of the materials it has produced, said Whiteley.

“We have explored a variety of commercial applications but determined that human-grade protein will be the most viable first market,” said Whiteley. “CRI has given us the flexibility to make these pivots and rapidly iterate the manufacturing process and product.”

Also, while working with mentors and other professionals at the Polsky Center for Entrepreneurship and Innovation at the University of Chicago, Whiteley and Huggins refined their entrepreneurial skills by testing several business hypotheses. Emergy went through several pivots before finding a sweet spot in protein production. Leveraging Emergy’s underlying technologies and expertise, they started working on growing what they call “better than meat” products that have the look and feel of animal-based whole muscle meat with all the fiber and nutrients of vegetables.

“Argonne has given us credibility and a stamp of approval that this is a viable technology and Argonne also helped to create our reputations in this field,” said Huggins. “CRI also gave us a safe place to explore and to fail and to learn and to test the waters on how we could succeed in business. We were able to develop business skills and it rounded us out as business professionals.”

Being embedded at Argonne also provided a turnkey lab for Whiteley and Huggins to work in and to start developing their process. With all the equipment and analytical tools they needed already in place, they could get to work quickly, which saved them time and money.

“I’ve enjoyed the opportunity to work alongside world-class scientists,” said Whiteley. “I will probably never get this opportunity again to work so intimately at a national laboratory.”

Now with a revised business plan and several prototypes in hand, Emergy could begin to sell a sustainable and edible protein product to consumers in coming years, aiming to make it a mainstream protein source, such as a protein powder or meat alternative.

While a release date for Emergy’s first product is still being determined, Huggins and Whiteley are confident the world will witness drastic changes in the food we eat and how it is produced in the next few years.

Read more about the impact of CRI innovators.